Operating as an essential business during the COVID-19 crisis is both an honor and a challenge. While Eagle Group companies have maintained continuous production, we have made a number of changes to our daily operations in order to maximize safety and clearly communicate new policies. Many of the lessons we’ve learned can be adopted by other manufacturing businesses as they prepare to reopen.

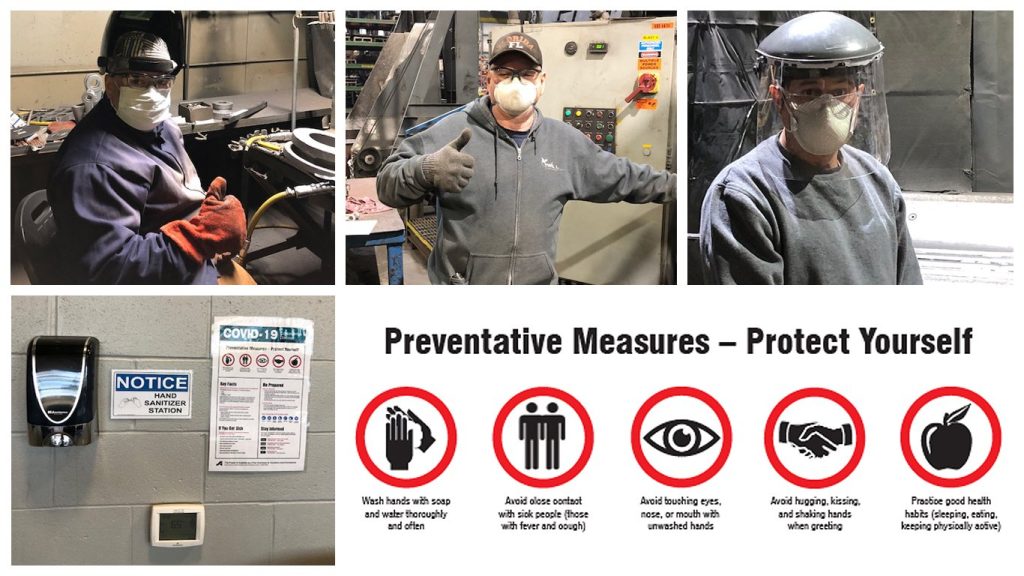

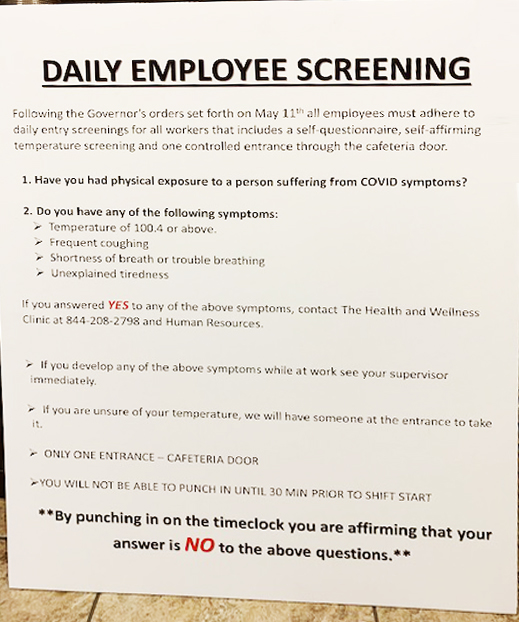

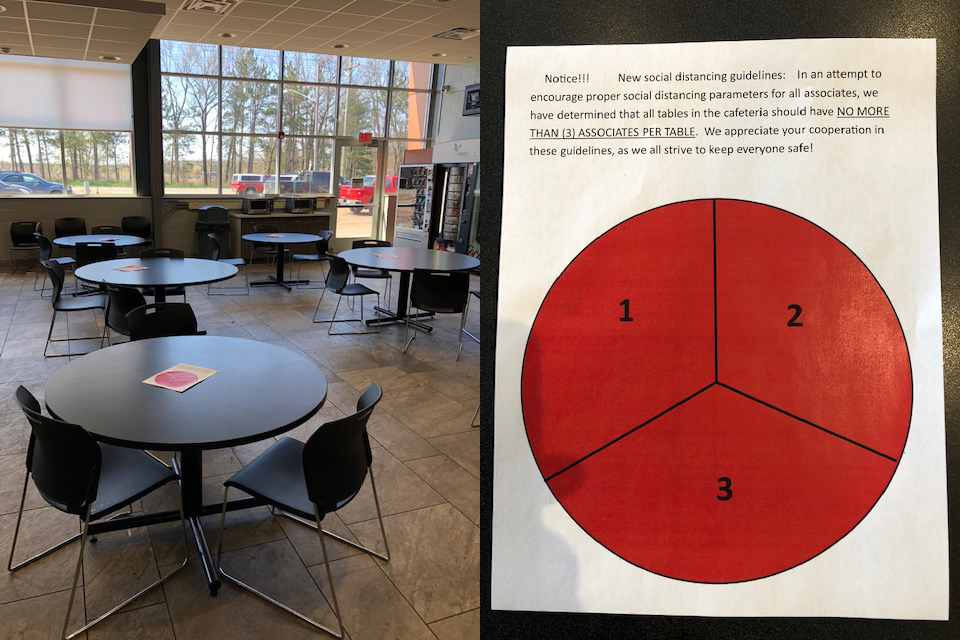

Health and safety has been our foremost concern throughout the crisis. Eagle Group companies have added touch-free hand sanitizers throughout the buildings, instituted twice-daily sterilization of common areas and begun carrying out weekly treatments with antimicrobial fogger. Eagle CNC has provided every worker with CDC-recommended PPE, including face masks and gloves. Break rooms have been reconfigured to encourage social distancing, and break schedules have been staggered so that fewer people are in common areas at the same time. To maximize safety, many of these policies will remain in place long after the threat of COVID-19 has dissipated.

Health and safety has been our foremost concern throughout the crisis. Eagle Group companies have added touch-free hand sanitizers throughout the buildings, instituted twice-daily sterilization of common areas and begun carrying out weekly treatments with antimicrobial fogger. Eagle CNC has provided every worker with CDC-recommended PPE, including face masks and gloves. Break rooms have been reconfigured to encourage social distancing, and break schedules have been staggered so that fewer people are in common areas at the same time. To maximize safety, many of these policies will remain in place long after the threat of COVID-19 has dissipated.

COVID-19 education has also been an important part of our efforts. Employees who fully understand the reasons for increased safety measures and production changes are more likely to follow guidelines. Our companies post daily COVID-19 updates to inform employees of coronavirus statistics affecting the local region as well as the companies themselves. Our external communications show everyone in our community why we are keeping our doors open. Dedicated social media posts, emails and announcements explain our essential role to employees, their families and the public. Our work has even been recognized by our district’s Member of Congress, who sent thank-you letters to our employees.

The Eagle Group relies on its employees now more than ever, and so we strive to minimize the stress that comes with their responsibilities. All employees who are able to work from home are doing so, and we have been able to adjust work schedules to accommodate changing needs like childcare and healthcare. Our on-site medical clinics are in full operation, providing touch-less temperature readings and evaluating any employee who feels unwell. In order to better compensate employees during this difficult time, Eagle Alloy and Eagle Precision have instituted a “Patriot Pay” system providing weekly bonuses based on hours worked. Eagle CNC has increased wages across the board.

The Eagle Group relies on its employees now more than ever, and so we strive to minimize the stress that comes with their responsibilities. All employees who are able to work from home are doing so, and we have been able to adjust work schedules to accommodate changing needs like childcare and healthcare. Our on-site medical clinics are in full operation, providing touch-less temperature readings and evaluating any employee who feels unwell. In order to better compensate employees during this difficult time, Eagle Alloy and Eagle Precision have instituted a “Patriot Pay” system providing weekly bonuses based on hours worked. Eagle CNC has increased wages across the board.

Despite all of our successes, operating through the COVID-19 pandemic as an essential business has presented a number of challenges. Both up and down the supply chain, our partners and customers are experiencing closures. Many customers have pushed out delivery dates, and some have canceled orders. We have had to work with our essential suppliers to ensure that they are able to provide us with the materials and products we need to keep production going. Our manufacturing community has been supportive: our customers show flexibility with deadlines when we have supply challenges, just as we are flexible with our own suppliers.

Effective leadership at every level has made it possible for the Eagle Group to stay in production. Our own company leadership met early on at the start of the COVID-19 crisis to plan for employee, customer and company needs. These strategies have laid the blueprint for our continuing response. We ordered PPE and disinfecting equipment right away so we were prepared to meet safety requirements from the beginning. In order to navigate the crisis as it continues to unfold, we rely on official guidelines regarding social distancing, sanitation and regulatory measures. State and national representatives have kept us informed of new legislation, and we regularly coordinate with the local Sheriff’s office to ensure continued compliance with all essential statutes.

We at the Eagle Group look forward to the time when it is safe for businesses in our community, around the nation and around the world to reopen their doors. Now and in the future, we will continue to prioritize the safety of our employees as we work to provide high-quality castings and machined products to our customers.